Product Category

- Standard Magnets

- Customs Magnets

- Magnetic Assmblies

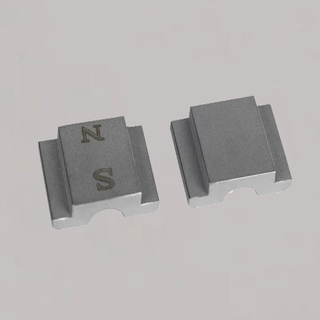

Alnico Irregular Magnets

Alnico irregular magnets

Alnico irregular magnets are crafted from an alloy consisting of aluminum, nickel, cobalt, and iron. These magnets are distinguished by their unique, non-standard shapes tailored to specific application requirements, making them versatile for complex design solutions. With excellent thermal stability, alnico irregular magnets can withstand temperatures up to 550 degrees Celsius, and their robust resistance to demagnetization ensures long-term reliability.

Typically produced through casting, this method allows for the creation of intricate shapes and sizes not achievable through standard manufacturing processes like sintering. The flexibility in shape enables optimal integration into custom assemblies where specific magnetic field directions and strengths are needed.

Used extensively in automotive, aerospace, and electronic industries, alnico irregular magnets are essential in applications where precise magnetic manipulation is crucial. Despite the advent of more potent rare earth magnets, the thermal resilience and structural versatility of alnico irregular magnets make them indispensable in many high-tech and industrial environments.