Product Category

- Standard Magnets

- Customs Magnets

- Magnetic Assmblies

Neodymium Magnet

We are professional Neodymium Magnet manufacturer and exporter in China. We can produce Neodymium Magnet (NdFeB magnet) according to your requirements. More types of Neodymium Magnet (NdFeB magnet), Sintered Neodymium Magnet (NdFeB magnet) wanted, please contact us right now.

General Introduction

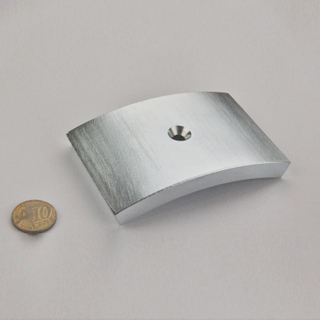

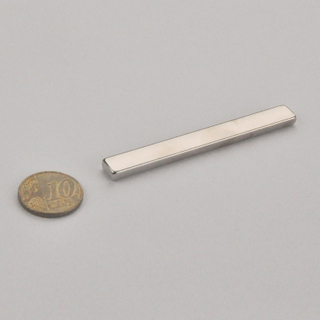

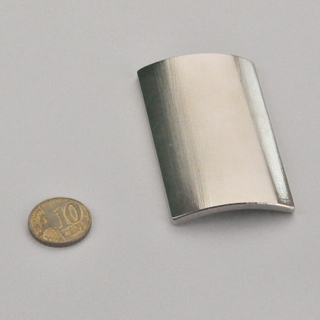

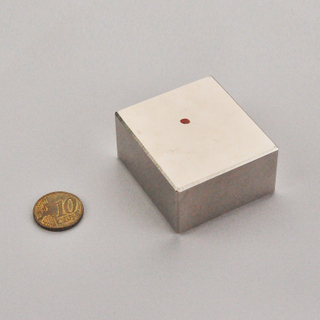

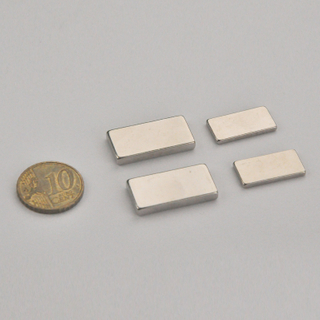

Sintered Neodymium Magnet is one of the high performance rare earth permanent magnets, which use neodymium (Nd), iron (Fe), and boron (B) as their main ingredients and is susceptible to demagnetization when exposed to elevated temperatures. Neodymium magnet is a new kind of magnetic material developed with excellent magnetic characteristics. These magnets are extremely strong for their small size, metallic in appearance and found in simple shapes such as rings, blocks and discs. There are many grades which can stand high temperatures, but several factors will dictate the performance of the Neodymium magnet.

Neodymium Magnet can be used in sensors, motors, filter automobiles, magnetic holders, loudspeakers, wind generators, medical equipments etc.

Neodymium Magnets have the characteristics of :

* Super strong Br Resident induction. Excellent demagnetization resistance capability.

Good Price relative to its high magnetic properties.

Coating is needed for Neodymium Magnet

* Surface Treatment Method: Type Information

Metallic Zinc, Nickel, Nickel + Nickel, Copper + Nickel, Nickel + Copper + Nickel,

Gold, Organic Epoxy, Nickel + Epoxy coating

Temporary Surface: Passivation

Dimension Available

Magnetic properties of Sintered Neodymium Magnet (NdFeB magnet):

Grade | Remanence | Coercive Force | Intrinsic Coercive Force | Max. energy product | Max. Operating Temperature |

Br mT (kGs) | Hcb kA/m (kOe) | Hcj kA/m (kOe) | ( BH )max kJ/m3 (MGOe) | Tw | |

N35 | 1170-1220 | ≥ 868 | ≥ 955 | 263-287 | 80 ℃ |

(11.7-12.2) | ( ≥ 10.9) | ( ≥ 12) | (33-36) | ||

N38 | 1220-1250 | ≥ 899 | ≥ 955 | 287-310 | 80 ℃ |

(12.2-12.5) | ( ≥ 11.3) | ( ≥ 12) | (36-39) | ||

N40 | 1250-1280 | ≥ 907 | ≥ 955 | 302-326 | 80 ℃ |

(12.5-12.8) | ( ≥ 11.4) | ( ≥ 12) | (38-41) | ||

N42 | 1280-1320 | ≥ 915 | ≥ 955 | 318-342 | 80 ℃ |

(12.8-13.2) | ( ≥ 11.5) | ( ≥ 12) | (40-43) | ||

N45 | 1320-1380 | ≥ 923 | ≥ 955 | 342-366 | 80 ℃ |

(13.2-13.8) | ( ≥ 11.6) | ( ≥ 12) | (43-46) | ||

N48 | 1380-1420 | ≥ 923 | ≥ 876 | 366-390 | 80 ℃ |

(13.8-14.2) | ( ≥ 11.6) | ( ≥ 12) | (46-49) | ||

N50 | 1400-1450 | ≥ 796 | ≥ 876 | 382-406 | 60 ℃ |

(14.0-14.5) | ( ≥ 10.0) | ( ≥ 11) | (48-51) | ||

N52 | 1430-1480 | ≥ 796 | ≥ 876 | 398-422 | 60 ℃ |

(14.3-14.8) | ( ≥ 10.0) | ( ≥ 11) | (50-53) | ||

30M | 1080-1130 | ≥ 796 | ≥ 1114 | 223-247 | 100 ℃ |

(10.8-11.3) | ( ≥ 10.0) | ( ≥ 14) | (28-31) | ||

33M | 1130-1170 | ≥ 836 | ≥ 1114 | 247-263 | 100 ℃ |

(11.3-11.7) | ( ≥ 10.5) | ( ≥ 14) | (31-33) | ||

35M | 1170-1220 | ≥ 868 | ≥ 1114 | 263-287 | 100 ℃ |

(11.7-12.2) | ( ≥ 10.9) | ( ≥ 14) | (33-36) | ||

38M | 1220-1250 | ≥ 899 | ≥ 1114 | 287-310 | 100 ℃ |

(12.2-12.5) | ( ≥ 11.3) | ( ≥ 14) | (36-39) | ||

40M | 1250-1280 | ≥ 923 | ≥ 1114 | 302-326 | 100 ℃ |

(12.5-12.8) | ( ≥ 11.6) | ( ≥ 14) | (38-41) | ||

42M | 1280-1320 | ≥ 955 | ≥ 1114 | 318-342 | 100 ℃ |

(12.8-13.2) | ( ≥ 12.0) | ( ≥ 14) | (40-43) | ||

45M | 1320-1380 | ≥ 995 | ≥ 1114 | 342-366 | 100 ℃ |

(13.2-13.8) | ( ≥ 12.5) | ( ≥ 14) | (43-46) | ||

48M | 1360-1430 | ≥ 1027 | ≥ 1114 | 366-390 | 100 ℃ |

(13.6-14.3) | ( ≥ 12.9) | ( ≥ 14) | (46-49) | ||

50M | 1400-1450 | ≥ 1033 | ≥ 1114 | 382-406 | 100 ℃ |

(14.0-14.5) | ( ≥ 13.0) | ( ≥ 14) | (48-51) | ||

30H | 1080-1130 | ≥ 796 | ≥ 1353 | 223-247 | 120 ℃ |

(10.8-11.3) | ( ≥ 10.0) | ( ≥ 17) | (28-31) | ||

33H | 1130-1170 | ≥ 836 | ≥ 1353 | 247-271 | 120 ℃ |

(11.3-11.7) | ( ≥ 10.5) | ( ≥ 17) | (31-34) | ||

35H | 1170-1220 | ≥ 868 | ≥ 1353 | 263-287 | 120 ℃ |

(11.7-12.2) | ( ≥ 10.9) | ( ≥ 17) | (33-36) | ||

38H | 1220-1250 | ≥ 899 | ≥ 1353 | 287-310 | 120 ℃ |

(12.2-12.5) | ( ≥ 11.3) | ( ≥ 17) | (36-39) | ||

40H | 1250-1280 | ≥ 923 | ≥ 1353 | 302-326 | 120 ℃ |

(12.5-12.8) | ( ≥ 11.6) | ( ≥ 17) | (38-41) | ||

42H | 1280-1320 | ≥ 955 | ≥ 1353 | 318-342 | 120 ℃ |

(12.8-13.2) | ( ≥ 12.0) | ( ≥ 17) | (40-43) | ||

45H | 1300-1360 | ≥ 963 | ≥ 1353 | 326-358 | 120 ℃ |

(13-13.6) | ( ≥ 12.1) | ( ≥ 17) | (43-46) | ||

48H | 1370-1430 | ≥ 995 | ≥ 1353 | 366-390 | 120 ℃ |

(13.7-14.3) | ( ≥ 12.5) | ( ≥ 17) | (46-49) | ||

30SH | 1080-1130 | ≥ 804 | ≥ 1592 | 223-247 | 150 ℃ |

(10.8-11.3) | ( ≥ 10.1) | ( ≥ 20) | (28-31) | ||

33SH | 1130-1170 | ≥ 844 | ≥ 1592 | 247-271 | 150 ℃ |

(11.3-11.7) | ( ≥ 10.6) | ( ≥ 20) | (31-34) | ||

35SH | 1170-1220 | ≥ 876 | ≥ 1592 | 263-287 | 150 ℃ |

(11.7-12.2) | ( ≥ 11.0) | ( ≥ 20) | (33-36) | ||

38SH | 1220-1250 | ≥ 907 | ≥ 1592 | 287-310 | 150 ℃ |

(12.2-12.5) | ( ≥ 11.4) | ( ≥ 20) | (36-39) | ||

40SH | 1240-1280 | ≥ 939 | ≥ 1592 | 302-326 | 150 ℃ |

(12.5-12.8) | ( ≥ 11.8) | ( ≥ 20) | (38-41) | ||

42SH | 1280-1320 | ≥ 987 | ≥ 1592 | 318-342 | 150 ℃ |

(12.8-13.2) | ( ≥ 12.4) | ( ≥ 20) | (40-43) | ||

45SH | 1320-1380 | ≥ 1003 | ≥ 1592 | 342-366 | 150 ℃ |

(13.2-13.8) | ( ≥ 12.6) | ( ≥ 20) | (43-46) | ||

28UH | 1020-1080 (10.2-10.8) | ≥ 764 | ≥ 1990 | 207-231 | 180 ℃ |

( ≥ 9.6) | ( ≥ 25) | (26-29) | |||

30UH | 1080-1130 (10.8-11.3) | ≥ 812 | ≥ 1990 | 223-247 | 180 ℃ |

( ≥ 10.2) | ( ≥ 25) | (28-31) | |||

33UH | 1130-1170 | ≥ 852 | ≥ 1990 | 247-271 | 180 ℃ |

(11.3-11.7) | ( ≥ 10.7) | ( ≥ 25) | (31-34) | ||

35UH | 1180-1220 | ≥ 860 | ≥ 1990 | 263-287 | 180 ℃ |

(11.8-12.2) | ( ≥ 10.8) | ( ≥ 25) | (33-36) | ||

38UH | 1220-1250 | ≥ 876 | ≥ 1990 | 287-310 | 180 ℃ |

(12.2-12.5) | ( ≥ 11.0) | ( ≥ 25) | (36-39) | ||

40UH | 1240-1280 | ≥ 899 | ≥ 1990 | 302-326 | 180 ℃ |

(12.5-12.8) | ( ≥ 11.3) | ( ≥ 25) | (38-41) | ||

28EH | 1040-1090 | ≥ 780 | ≥ 2388 | 207-231 | 200 ℃ |

(10.4-10.9) | ( ≥ 9.8) | ( ≥ 30) | (26-29) | ||

30EH | 1080-1130 (10.8-11.3) | ≥ 812 | ≥ 2388 | 223-247 | 200 ℃ |

( ≥ 10.2) | ( ≥ 30) | (28-31) | |||

33EH | 1130-1170 | ≥ 836 | ≥ 2388 | 247-271 | 200 ℃ |

(11.3-11.7) | ( ≥ 10.5) | ( ≥ 30) | (31-34) | ||

35EH | 1170-1220 | ≥ 876 | ≥ 2388 | 263-287 | 200 ℃ |

(11.7-12.2) | ( ≥ 11.0) | ( ≥ 30) | (33-36) | ||

38EH | 1220-1250 | ≥ 899 | ≥ 2388 | 287-310 | 200 ℃ |

(12.2-12.5) | ( ≥ 11.3) | ( ≥ 30) | (36-39) | ||

30AH | 1080-1120 | ≥ 812 | ≥ 2785 | 223-255 | 220 ℃ |

(10.8-11.2) | ( ≥ 10.2) | ( ≥ 35) | (28-32) | ||

33AH | 1120-1170 | ≥ 812 | ≥ 2785 | 247-271 | 220 ℃ |

(11.2-11.7) | ( ≥ 10.2) | ( ≥ 35) | (31-34) |

Physical and Mechanical Properties of Neodymium Magnet:

Thermal Conductivity | 7.7 kcal/m-h-°C |

Young’s Modulus | 1.7 x 104 kg/mm² |

Bending Strength | 24 kg/mm² |

Compressive Strength | 80 kg/mm² |

Electrical Resistivity | 160 µ-ohm-cm/cm² |

Density | 7.4-7.55 g/cm³ |

Vickers Hardness | 500 - 600 |

Available coatings for sintered Neodymium Magnet (NdFeB magnet):

Available Coatings: | ||||

Surface | Coating | Thickness (Microns) | Color | Resistance |

Passivation | 1 | Silver Grey | Temporary Protection | |

Nickel | Ni+Ni | 10-20 | Bright Silver | Excellent against Humidity |

Ni+Cu+Ni | ||||

Zinc | Zn | 8-20 | Bright Blue | Good Against Salt Spray |

C-Zn | Shinny Color | Excellent Against Salt Spray | ||

Tin | Ni+Cu+Sn | 15-20 | Silver | Superior Against Humidity |

Gold | Ni+Cu+Au | 10-20 | Gold | Superior Against Humidity |

Copper | Ni+Cu | 10-20 | Gold | Temporary Protection |

Epoxy | Epoxy | 15-25 | Black, Red, Grey | Excellent Against Humidity & Salt Spray |

Ni+Cu+Epoxy | ||||

Zn+Epoxy | ||||

Chemical | Ni | 10-20 | Silver Grey | Excellent Against Humidity |

Parylene | Parylene | 5-20 | Grey | Excellent Against Humidity, Salt Spray. Superior Against Solvents, Gases, Fungi and Bacteria. FDA Approved. |