Product Category

- Standard Magnets

- Customs Magnets

- Magnetic Assmblies

Customs Magnets

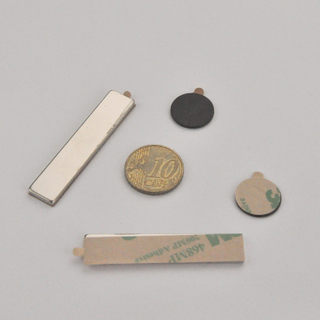

Custom magnets are specially designed to meet the unique specifications and requirements of specific applications. These magnets can be crafted from various magnetic materials, including neodymium, ferrite, alnico, and samarium cobalt, depending on the needed strength, resistance to demagnetization, temperature stability, and environmental resilience.

The customization allows for a variety of shapes, sizes, and strengths to be produced, including complex forms like arcs, countersunk, and irregular shapes, catering to a wide range of industrial, commercial, and consumer uses. Common applications for custom magnets include automotive sensors, electronic devices, medical equipment, and specialized industrial machinery.

Manufacturers often use advanced fabrication techniques such as sintering, injection molding, and machining to create these tailored magnetic solutions. This level of customization is crucial for integrating magnets into products where standard off-the-shelf magnets would not suffice, providing flexibility in design and functionality that is essential for innovative technological applications. Custom magnets are particularly valuable for their ability to fit precise design criteria and enhance the performance of the products they are incorporated into.